Vietnamese Knife Making

Recently we went to Hanoi for a long weekend. Weather-wise, not exactly the best time to go there considering it was about 55 degrees at night and if we were lucky, 70 degrees (and rainy) during the day. There will be more to come on our Hanoi vacation, but today I’m touching on one experience we did through Airbnb. We each made a knife at a small village/neighborhood on the outskirts of Hanoi.

In Advance

Generally when traveling, we look at Airbnb experiences for ideas on potential activities. The overall Airbnb platform has jumped the shark, the experiences part of the site is still pretty solid. Often these experiences fall into 5 categories:

1. Food tour (a favorite)

2. Photo/selfie tour (miss me)

3. Walking/history tours

4. Arts, crafts and cooking classes

5. Day tours

When a locale has a unique craft tour it is almost always worth a deeper look. We’re not looking to accumulate more stuff, but if we can attach a memory to an experience and an object that will last, we’ll often go for it. Neither of us has ever made a knife before, though we’ve watched the History Channel classic Forged in Fire a time or two. Let’s do a personal FiF! Here’s the process we went through.

Getting There

45 minutes Southwest of Hanoi is an area called Kien Hung that was once a small village and is now urbanizing fairly quickly. It is known for its blacksmiths; aside from the shop we visited I noticed a few other shops even though it was Sunday morning before the Lunar New Year. We got dropped off at an intersection where everything was closed; as we got out the driver got out too and just walked off into the bushes! I think he was going to pee (there’s seemingly no shame in SE for dudes to just stroll off and piss somewhere randomly) but it made us very confused on what was to happen next. Turns out the shop was about a block away, but because the area is so po-dunk it’s difficult for rideshare apps to figure out the right address.

Our Host and the Process

Our Airbnb host had been running the tour for 11 years, wow! Very nice woman who decided corporate life wasn’t for her and then shifted to spreading local culture and tradition to tourists. The actual blacksmith was an old lady wearing plastic flip flops and sweat pants. Amusingly, the Airbnb listing told us to be sure to wear long pants and long sleeved shirts for protection and this lady is basically wearing pajamas. The forge inside this garage shop was just a stack of bricks in the corner. Wild how little tech is needed to create high carbon steel blades.

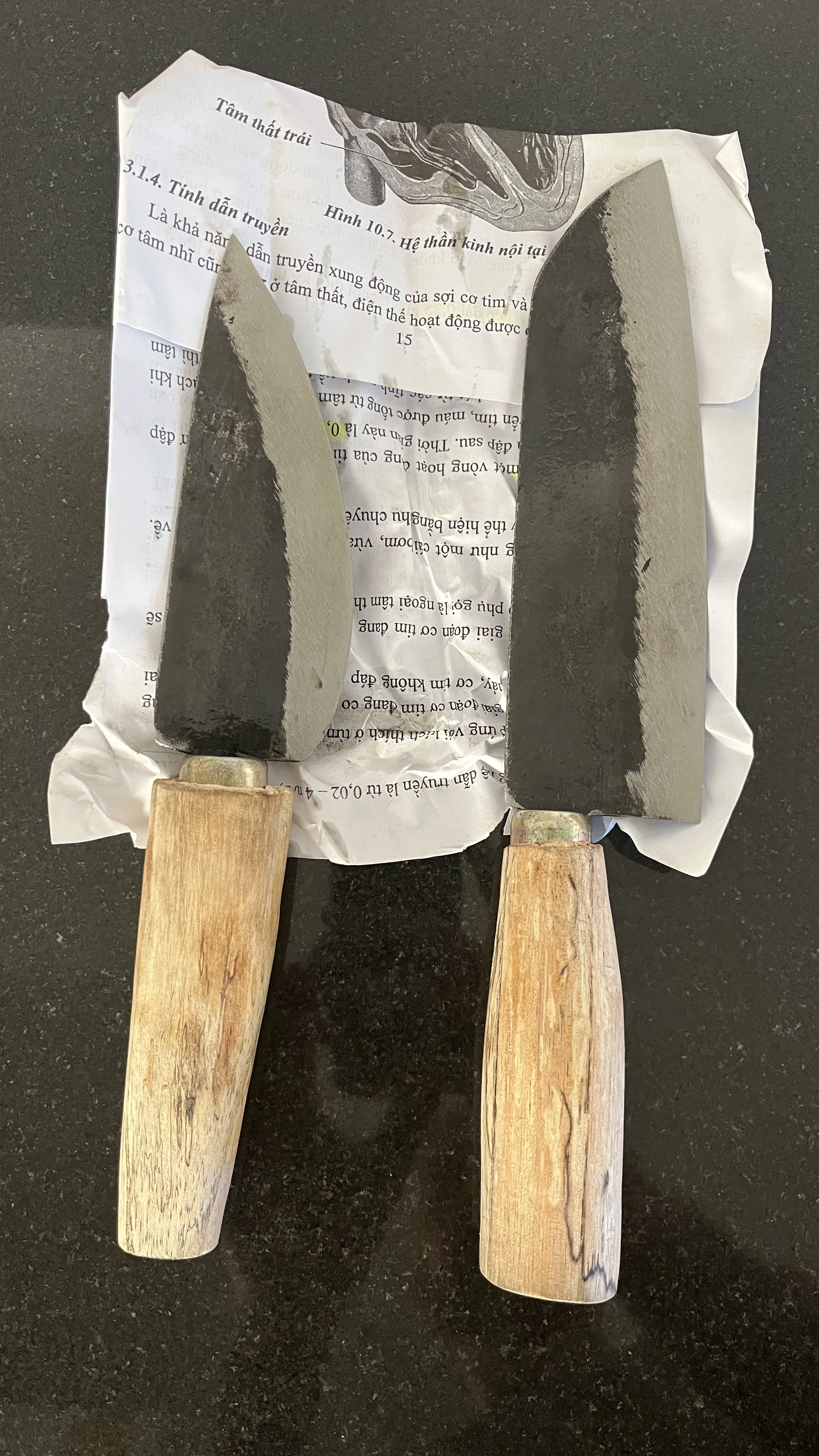

After a history lesson on the area and Vietnamese knives, we selected our knife shapes. Amber went with the traditional curved blade and since we didn’t want 2 of the same design, I drew a custom shape similar to a Japanese santoku knife. Pretty wild to use a pen and some scrap paper and have it in my hand as a sharpened blade in less than 3 hours.

Froggy Went a Whittlin’

Once we chose our designs, we started whittling handles. The whittling knife was a hooked blade on the end of a piece of bamboo; we shoved the bamboo in our armpit and then pulled the handle against it. This was the most time consuming part of the journey and definitely the most frustrating. Trying to whittle an even, consistent shape for a handle is not easy. We could have whittled all day if we had the time! Little did we know that we then had to delicately chop away the end of the handle so we could put a ring on the end. Sanding…so much sanding. What I would have given to have a belt sander, just smoothing that thing out until it’s as smooth as a bowling lane.

Knives Start to Take Shape

As the forge got hot, we traced our blade designs onto knife blanks (strips of high carbon steel.) She then held a pointed tool along the edges of our blanks and we used sledgehammers to smash the edges off and get it into the rough final shape. After that she heated the blade and we took turns smashing it with a hammer to temper it. After a few rounds of this (and whittling in the background) the basic shape of the blade was good to go. At this point it was more of a knife shaped chunk of metal than an actual knife, but we were on our way.

Working the Edge

Next we used an old ass grinding wheel (that she kept on a scooter tire) to start to form the cutting edge of the blade. The stick we used to keep even pressure on the blade was probably older than we are. This was very much a team effort; while Amber and I each had a turn at working our own edge, Granny Blacksmith definitely did the heavy work to actually get it closer to an actual knife. At this point, the balance between the labor we did and the labor she did started to tilt in her direction. Most anyone can swing a hammer for a few minutes on a piece of metal, but when it comes to actually turning it into a sharp knife, you need knowledge and experience.

Inserting the Blade into the Handle

It was a nerve wracking experience when it came to marking the handle for the tang (the part of the blade that extends into the handle) to be inserted. Now, I don’t know much about knives but I do know the longer the tang, the better. These tangs were relatively short (about ⅓ of the blade) and pointed at the end. We drew a line on the handle where we thought the tang should go, and then just bashed the blade into the handle by slamming it on her anvil. Nothing scientific or fancy, just good old fashioned brute force. We got a few attempts at this as well, but again she had the final strokes to ensure it was solid, straight and usable.

Sharpening the Edge and Wrapping Up

With the handle on and the blade honed, the final step was to get the final edge on it with a limestone block. This was a tricky proposition! Amber and I did the best we could with our limited muscle memory, but left the final final sharpening to our Vietnamese obi wan. We both decided we would rather have the sharpest knife possible, done by an expert, than a semi-jabroni version that was done by us. Start to finish, the process took about 3 1/2 hours.

Final Thoughts

It wasn’t that fun to get up at 730 am on a vacation, but the journey was well worth it. These knives will last forever as long as we take care of them (and they do take a bit of maintenance with oiling and cleaning by hand, no dishwasher) and they’ll always be a reminder of the weekend we spent in Hanoi. Blacksmithing is a dying trade, even in Vietnam. Granny Blacksmith has been doing it for 40 years; her husband has died and her kids aren’t interested in continuing. Once she’s gone, who knows what will become of the business. So to get time with her and to build something we’ll remember forever was an honor and a privilege.

PS: Check out our awesome new layout! If you notice anything that doesn’t work correctly or causes issues, please let us know so we can work out the kinks.